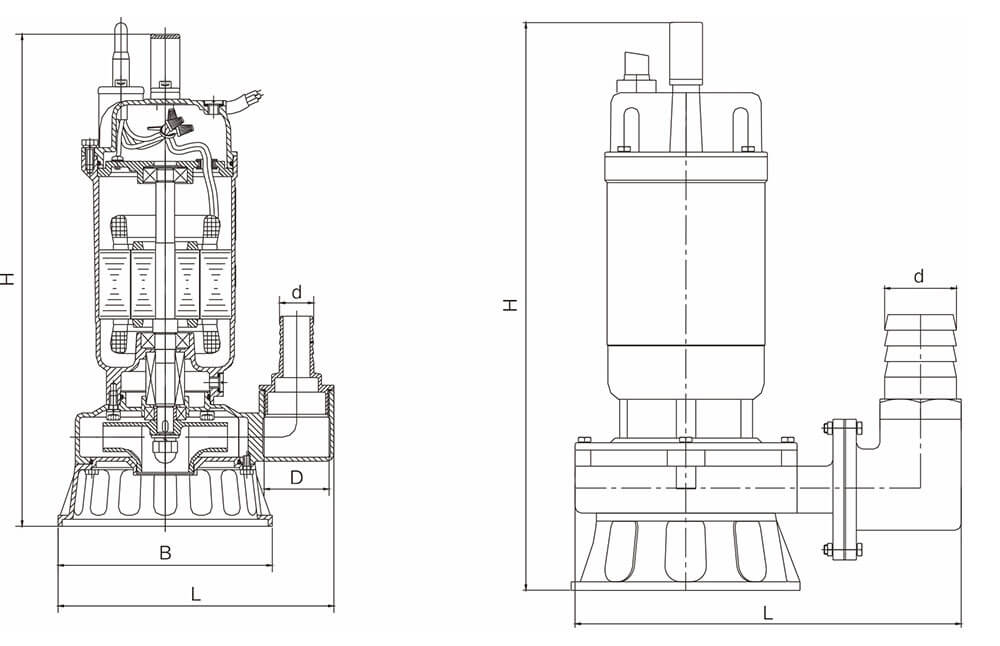

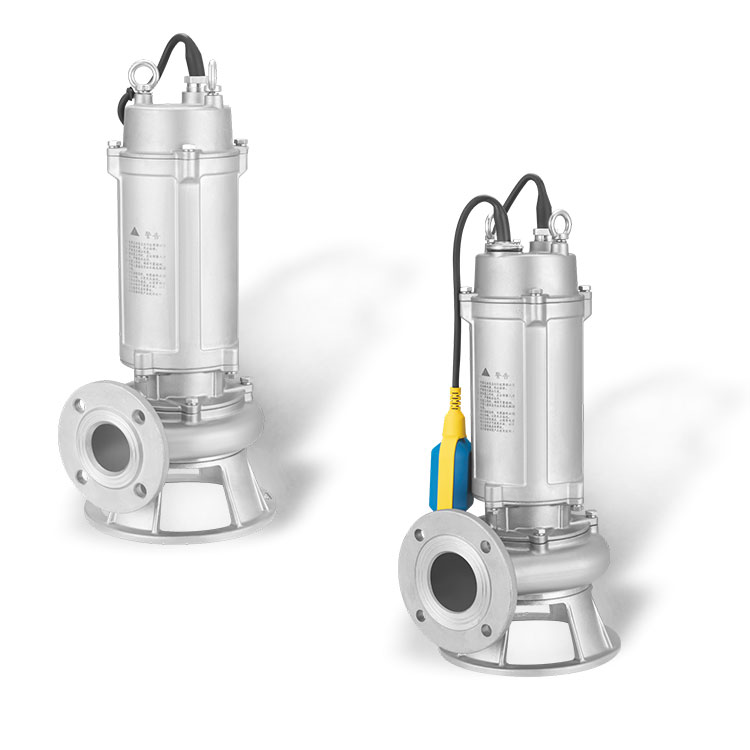

The WQ(D)-S series of all-stainless steel precision cast sewage submersible pumps adopt a unique single and double channel impeller structure, greatly improving the passing ability of dirt.

1. The oil chamber adopts fluorine rubber double-end mechanical seals, and the outer chamber adopts a single-end fluorine rubber mechanical seal structure, effectively reducing the problem of water ingress caused by friction between sand and the shaft, resulting in shaft wear.

2. The motor adopts vacuum impregnation to achieve Class F insulation, and is equipped with a thermal protection device, effectively extending the service life of the pump.

3. The precision cast pump casing is lightweight, corrosion-resistant, energy-saving, beautiful in appearance, hygienic, and environmentally friendly.

4. The electric pump is equipped with an overheat (<2.2kW) and current protector (2.2~4kW) to prevent motor overload and overheating.

5. Anti-corrosion cables, PTFE mechanical seals, and high-temperature resistant motors can be customized according to customer requirements. (Suitable for use in environments with liquid temperatures ≤100℃).

It's suitable for building construction, hospitals, residential areas, municipal engineering, road traffic and construction, chemical plating, factory sewage, aquaculture, pharmacy, beverages, seawater and brine, solid particles contained in general corrosive media, long fiber wastewater, sewage.